Oil seals are essential to retaining lubricants and preventing the ingress of dirt and moisture in machines and industrial equipment. Made from durable, wear-resistant materials, seals help extend equipment lifespan and ensure reliable performance. Oil seal profiles come in many designs, and are categorized according to their function and how they interact with surrounding components.

As a trusted leader in sealing products, MSP Seals offers a wide range of fluid-retaining, general-purpose, and heavy-duty profiles to meet the demands of diverse industrial applications. Learn more about our comprehensive selection of Types A, B, and C seal profiles.

Type A: Fluid-Retaining Profiles

Type A seal profiles are designed for fluid retention applications, and in product codes, the letter “A” signifies fluid-retaining capabilities. These seals act as a barrier, preventing oil, lubricant, and process fluids from escaping a mechanical system. Fluid-retaining profiles are developed for performance in high-pressure systems, creating and maintaining a strong seal that prevents leaks.

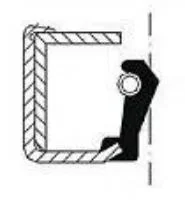

Single-Lip (SA2)

SA2 seals are designed for fluid retention applications with high- and low-viscosity fluids, moderate pressure, and moderate speeds. They have a thin, flexible lip edge that stays in constant contact with the rotating shaft, creating a tight seal. Since SA2 profiles lack a secondary lip, they provide less contaminant protection than other designs and are recommended for moderately clean environments. Some of the most common applications include:

Motors

Motors

Pumps

Pumps

Shaft sealing

Shaft sealing

Transmissions

Transmissions

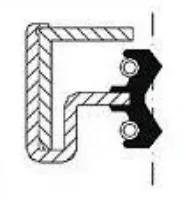

Double-Lip (TA2)

The TA2 profile has primary and secondary lips for enhanced sealing performance. A dust lip faces the external environment, blocking external contaminants, while the primary seal ensures fluids and lubricants do not leak. TA2 seal profiles are also reinforced with an integrated spring.

Double-lip profiles are ideal for sealing large diameter components that require extra support. After installation, they offer good stability and excellent radial rigidity. The TA2 profile is recommended for applications that require fluid retention and further protection from external debris, such as factories with high levels of airborne contaminants or pollution.

Two-Spring Lip

Two-spring lip seals feature two sealing lips that are each supported by a garter spring. The springs apply constant radial force to both sealing lips, creating a constant, tight barrier against the shaft. This design is ideal for high-speed, high-pressure applications where high sealing force is required.

Two-spring lip seals from MSP Seals form a strong, reliable barrier against leaks, effectively managing fluid pressure. Some of the most common applications for these profiles are in systems that need strong and reliable fluid retention and contaminant exclusion, such as:

Automotive transmissions

Automotive transmissions

High-pressure pump systems

High-pressure pump systems

Heavy machinery

Heavy machinery

Type B: General Purpose Profiles

Type B oil sea ls are versatile, general purpose profiles that are suitable for a wide range of oil sealing applications. In product codes, the letter “B” indicates general purpose utility. These seals have balanced performance, retaining fluids and blocking contaminants. Type B seals come in both single- and double-lip designs, with and without a spring, and are used widely across industrial applications.

- Configurations

Type B seals come in two primary configurations: single lip (SB) and double lip (TB2). Single lip seals are intended for applications that only require fluid retention, such as in basic motor bearings. Double lip designs provide added protection against external contaminants and are the preferred option for dusty or dirty operating environments, such as within agriculture or construction applications.

- Optional Spring

Many Type B seals include an optional garter spring to provide constant radial sealing force. Garter springs are a type of coiled wire that fits into a groove on the seal’s lip. As the lip wears down throughout its service life, the garter seal maintains tight pressure, extending the seal’s lifespan. Type B seals with springs are essential in applications where the shaft experiences eccentricity.

- Adaptable Design

Type B oil seal profiles are designed to be versatile. They come in many material options, including silicone, Viton (FKM), and nitrile rubber (NBR), for compatibility with diverse operating environments. Each seal is tailored to your application’s needs with materials selected based on shaft speed, pressure, temperature, and other factors. Depending on the material, Type B seals can withstand exposure to many chemicals, temperature ranges, and operating conditions. They are used in everything from automotive transmissions to industrial gearboxes.

Type C: General Purpose and Protective Profiles

Type C oil shaft seal profiles are heavy-duty products with robust sealing capabilities. A “C” in product codes indicates that the seal has a reinforced design for extra durability and sealing power. They are designed with maximum protection and durability in mind, featuring solid construction and high-performance materials. Type C profiles have an added dust lip that provides protection against external contaminants and are compatible with soft alloys, plastics, steel, and cast iron housings.

While Type C seals share many similarities with Type B products, they can handle more harsh and demanding operating conditions. In general protective or sealing applications, Type C seals are a reliable yet still cost-effective solution.

- Solid Construction

Type C seals are known for their sturdy construction. The metal casing acts as a rigid shell for a secure, press-fit that keeps the seal firmly in place within a housing or bore. Type C seals are ideal for applications with high vibration or dynamic loads, since they are designed to maintain stability. The most common applications for these products are in heavy machinery or large diameter shafts.

- Effective Sealing

One of the most significant ways that Type C profiles differ from A and B types is in their sealing capabilities. Type C oil seals have a metal insert for improved fit and reinforcement. The combination of flexible polymers and durable metal forms a tight fit between the housing and the seal itself, keeping contaminants out and lubricants in. This reliable barrier performs consistently throughout a long service life, with minimal need for maintenance.

- Contaminant Protection

The primary function of a Type C seal is to provide effective protection against the ingress of dust, dirt, and other airborne particles. Their robust design and tight fit make them well-suited for applications in dirty or harsh environments, such as construction equipment, agricultural machinery, and heavy industrial gearboxes. Double-Lip (TC) and Single-Lip (SC) configurations, with or without springs, make these seals suitable for many types of applications that balance fluid retention with external protection.

The information provided in this resource guide is for general informational purposes only and is not intended as specific guidance or instruction. Each application is unique, and the MSP team can assist in selecting materials or solutions best suited to your specific requirements.